Panelboards are a vital part of any residential occupancy. Here, you’ll learn the components of an electrical Panelboard, as well as circuit breaker types and functions.

Residential Main Service Panelboard and Subpanel

The Panelboard is mounted in the wall, controlling and distributing power to branch circuits in the house. Subpanels are typically added to distribute power and gain local control of branch circuits such as garages and workshops, and also allow for more circuits to be installed at some point in the future.

The main components of a grounded residential main service Panelboard:

- Overcurrent devices: Circuit breakers

- Conductors: Single phase – 240 volt (2 legs)

- Neutral conductor: white (identified)120 volts N to L1 or N to L2

- Equipment Grounding Conductor (EGC) which terminates on the ground bus in the Main Panelboard

- The Grounding Electrode Conductor (GEC) which terminates on the ground bus in the Main Panelboard and the ground (ground rods)

- Main Bonding Jumper: bridge between the ground bus and neutral bus

How Panelboards Work

Single phase: A cable or conductors supply 120/240 volt to the Main Panelboard and terminate on the Main circuit breaker lugs, which are considered (2) legs typically referred to as L1 and L2. Each leg measures 120 volts between Neutral. The Main circuit breaker connects the to left and right busbars and the Neutral terminates to the Neutral busbar with Main bonding jumper.

Single pole circuit breakers (120volts), as well as Double pole circuit breakers (240 volts), connect between the busbars and the branch circuits.

Power Loads: Electric ranges and clothes dryers operate on a 120 volt/240 volt system (L1,L2 Neutral and equipment grounding conductor) branch circuit conductors terminate on double circuit breakers and the neutral terminates on the neutral bus.

Neutral vs Effective Ground Path

To efficiently learn the system as a whole, you’ll need to know the difference between neutral and effective ground path.

- Neutral: Neutral refers to an insulated conductor that’s intended to carry current during normal operations, completing a circuit.

- Effective ground path: Consists of a combination of the Equipment Grounding Conductor and bonded metal parts and equipment. It’s non-current-carrying metal parts and equipment provide a low-impedance path that clear ground faults.

Circuit Breaker Functions

Circuit breakers are crucial to protecting branch circuits from overloads, short circuit and ground faults. Circuit breakers are switches that can safely open circuits and be locked open when it’s time to service/troubleshoot, isolate branch circuits, electrical devices and equipment. The amperage rating of a breaker is typically printed on the handle or switch. Other information on the breaker’s label might include:

- HACR (Heating/Air Conditioning/Refrigeration) rating — It can handle a brief surge in amperage that’s required for a compressor or other devices to start.

- SWD (Switch) — May be used as a switch to open or isolate branch circuits.

- AIC (Ampere Interrupting Capacity) rating — Could be as much as 10,000 amps, short circuit rating.

- Torque — Torquing is required for conductors terminating on mechanical lugs (wiring binding), expressed in lb-in and a torque screwdriver is a must for installation.

Finding Torque For Circuit Breakers

When terminating a conductor to a wire binding screw such as circuit breakers or mechanical lugs, proper torquing is a requirement of the National Electrical Code (NEC).

If the torque specification isn’t spelled out on the circuit breaker’s label, you may need to look at the manufacturer’s literature or website for the proper torque settings on the specific make/model of the circuit breaker.

Torque settings can differ according to the gauge of wire being used in the system. Some makes/models of the circuit breakers may have the torque specs and other information stamped into the side of the plastic casing, rather than on the label at the front.

Typical Residential Circuit Breakers

Residential circuit breakers and voltages include:

- Single Pole — 120 volts

- Tandem —120 volts (caution with multiwire branch circuits)

- Double Pole —𐑋240 volts

Circuit Breakers are designed to switch/isolate branch circuits to ON/OFF and TRIP. They protect the branch circuit insulation from excessive heat due to Overcurrent. This amperage combined with ambient temperature in excess of Circuit breaker rating, as well as, short circuit and ground faults, conduct high amperage due the low impedance path back to the source (effective ground path) TRIPS the circuit breaker.

- A Single pole circuit breaker is designed to protect 120 volt lighting loads such as receptacles, laundry room, kitchen, living rooms, etc.

- A Double pole circuit breaker is designed to protect 240 volt equipment such as Electric ranges, Electric dryers, Electric hot water tanks.

- Tandem circuit breakers use two single pole circuit breakers fitted into one single pole space. These help save space in the panelboard and leave room enough for other branch circuits to be added at some point.

How Circuit Breakers Work

Circuit Breakers are designed to handle a brief inrush in amperage above the rated capacity, which allows fan motors or compressors to run. The time that they can allow this inrush vs the actual amperage capacity they can handle during that time, is expressed on a Time/Amperage or “Trip” curve.

Depending on the design and the purpose of the breaker, it may be able to handle as much as 15x the usual load and might trip itself anywhere from milliseconds to 2-3 seconds later.

Breakers have three positions:

- On — closed circuit

- Trip — open circuit also indicates problem

- Off — open circuit

Understanding GFCI Breakers located in the Panelboards

GFCI Breaker stands for Ground Fault Circuit Interrupter not to be confused with GFCI receptacles, a GFCI Breaker’s function is to protect against electric shock, overloads, short circuit and ground faults, whereas GFCI receptacles protect against electric shock only.

GFCI protection is common for wet locations such as kitchen counters, bathrooms, basements, outside pools/spas and applications where water might be present and lead to a ground fault. GFCI protection is required by the NEC and must be readily accessible.

GFCI breakers are designed with a simple circuit board inside that monitors the current and amperage that’s routed through the breaker and then trips if it detects an imbalance in amperage of 5 mA, which could mean a ground fault.

For example, a120 volt branch circuit.10 amps on the branch circuit conductor to the Load (equipment) and 10 amps returning on the Neutral conductor would be a normal condition. 10 amps into the Load (equipment) and 9.9 amps returning indicates a ground fault of 100 mA which is enough to cause a serious or even fatal electrical shock. At that point, the circuit board would detect that difference of >5mA and would quickly trip the GFCI breaker.

The GFCI breakers will be labeled with amperage capacity suitability for HACR service, but also will be clearly labeled with their GFCI function. They feature a test button and a colored indicator that shows when a ground fault has occurred.

GFCI breakers branch circuit conductors terminate to the appropriate terminal on the load, while the Neutral conductor terminates on the Neutral terminal on the GFCI breaker rather than going straight to the Neutral bus. A separate pigtail from the GFCI breaker will then terminate to the Neutral bus. Learn more about GFCI Circuit Breaker vs Outlet: How To Protect Against Electric Shock in our blog post.

AFCI Breakers

Arc Fault Circuit Interrupter (AFCI) breakers feature a circuit board that can differentiate between a normal, momentary arc such as operating a light switch from a prolonged, arc-producing event. The AFCI breaker function is to detect those dangerous arcing conditions and trip, preventing an electrical fire.

Arcs (Parallel Arcing) can occur if insulation is frayed or pinched, allowing current to travel between hot and neutral wires. It can also occur if a nail or drywall screw penetrated a wire or damaged an internal wire inside an electrical cord. Due to the dangers posed by electrical arcs, the following provisions have been made:

- AFCI protection is now required by NEC (15 & 20 amp branch circuits) for living rooms, rec rooms, offices, kitchens, bedrooms, closets, laundry rooms and dens.

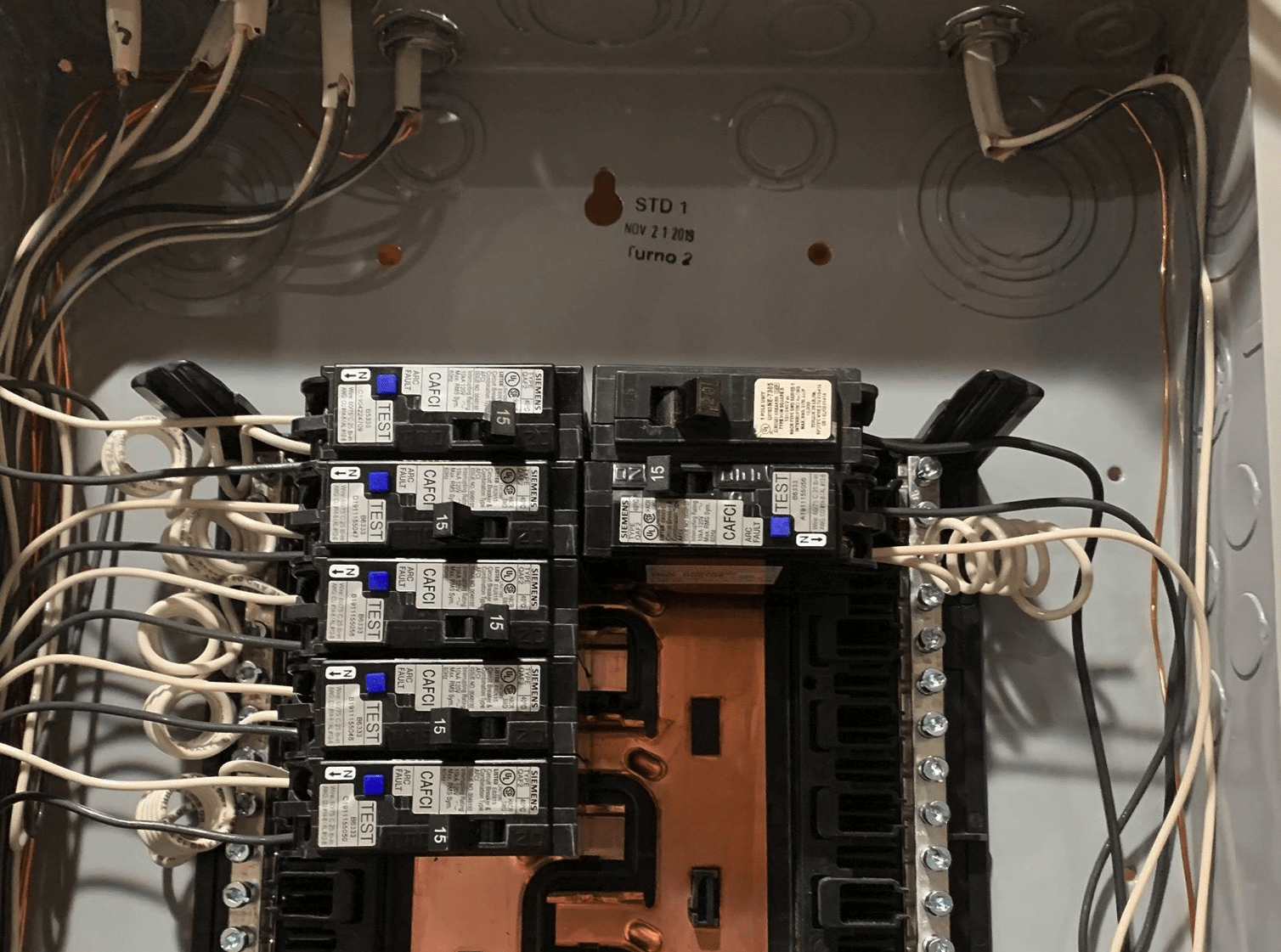

- AFCI breakers are clearly labeled on the front and feature a test button, as well as an Arc Fault indicator that shows when an arc fault has been detected.

- AFCI breakers’ labeling must include the HACR rating, amperage rating and AIC (short circuit rating).

CAFCI and Dual Function Breakers and AFCI Receptacles

While AFCI breakers can detect an arc that goes from Line to Neutral (parallel), CAFCI breakers are designed to detect a Line1-Line1 (series) arc such as inside an appliance’s damaged electrical cord. CAFCI breakers are labeled as Combination AFCI and don’t offer AFCI and GFCI protection together. That would call for a Dual Function breaker.

Dual function breakers are a fairly new innovation and offer the best possible package of protection. They are labeled for both AFCI and GFCI and have separate colored indicators that light up if an arc fault or a ground fault has occurred.

Additionally, AFCI breakers are required by the NEC if the device isn’t readily accessible.

Lockout/Tagout Safety Procedures

Circuit Breakers as an Isolation Device

Lockout/Tagout is a way to prevent a system from being energized by placing a lockout device/padlock and warning tag on the system’s isolation device. Often, when performing a lockout on a branch circuit to an electrical device, electrical equipment is supplied by a circuit breaker. Learn Everything You Need to Know About Lockout Tagout Procedures in our recent blog post.

Each tech is responsible for installing their own lock and tag on equipment to ensure “zero energy.” One key for that lock!

From there:

- A qualified person (OSHA/NFPA70E) performs the live-dead-live check and isolation.

- The lockout tag is signed by the person who installed it and is working on the system.

- Sometimes the system might be locked out by more than one person. To ensure safety, each individual has to remove their own lockout/tagout before the system can be energized again.

- Hasps for lockouts may have as many as six holes for separate padlocks; cables can be used to extend the lockout to a separate circuit breaker.

This breakdown of panelboards and different types of circuit breakers, their design and function, and basic safety procedures for electrical systems is a great start when entering the industry. For a more in-depth look into these areas, check out Interplay Learning’s Electrical course catalog.

Chad Soucy

Interplay Learning Electrical Expert

Chad is Interplay’s electrical expert and is a Master Electrician. Chad has progressed as an electrical professional throughout his career, with early beginnings in rewiring/wiring homes to QA/Commissioning plants, honing his skills in all aspects of the electrical trade along the way. He transitioned his career through Residential, Commercial and Industrial sites, and in 2012, further expanded on his mission to lifelong learning in becoming an electrical instructor. He continued on this path as an online course developer and is steadfastly committed to electrical safety and sound adult learning theories.