On the surface, a gas furnace might seem like a pretty simple setup to diagnose and repair, however, it’s actually a complex component to the overall system. Without the proper knowledge and training, HVAC techs can easily get stumped in the process.

Here are the 10 most common mistakes HVAC techs get wrong when gas furnace troubleshooting.

Mistake #1: Overlooking a Dirty Filter

Homeowners can sometimes forget about their furnace/HVAC filter, either not changing it often enough or at all. That’s why HVAC techs should start with the filter. A dirty filter can cause all kinds of issues such as:

- Restrictions in airflow, causing the heat exchanger to overheat and the unit to cycle off on the high limit. This can lead to premature failure of the heat exchanger.

- The inability to trap particles of dirt, dust, and pet dander, which will affect indoor air quality. This can really be a problem for people with asthma or other respiratory issues.

- Result in dirt, pollen, and dust coating the ductwork in the home — have a look at the registers and see if they’re covered with fuzz. Cause debris and particulate matter to collect on the blower wheel and the air conditioning system evaporator coil, resulting in reduced airflow

Mistake #2: Assuming That If All The Components Are Working, The System Must Be Working Properly

If everything looks okay on the surface but you’re still not getting any action out of the system this means you must take a closer look at each part of the system to figure out what’s failed. Helpful questions that can lead you in the right direction might be:

- How long has it been since the blower motor has been lubricated?

- Is the electronic ignition or pilot control working properly?

- If the thermostat is a battery-powered model, is the battery depleted?

- Is the limit switch for the blower functioning?

- Could a duct or a register be obstructed?

- Is the breaker for the furnace tripped?

- Is there a problem with the gas line feeding into the furnace? Is the petcock for the gas line open?

- Is the flame sensor for the burner positioned and working properly?

Mistake #3: Not Checking Factory Default Blower Speed

A blower within an HVAC system is responsible for pushing cold or hot air through the vents. It’s important not to assume that the factory default speed is correct. The blower speed is dependent on other factors in the system and isn’t a one-size-fits-all matter so sometimes it will need to be altered.

Things to take into account:

- Total BTU capacity of the system

- Size and total length of ducts in the system

- Size and style of air filter being used

- The differing speed requirements. Is the system natural-draft, induced-draft, 80%-plus or 90%-plus?

- The rated temperature rise. Adjust the blower speed until the temperature rise from return to supply air is within the range specified on the units dataplate

Formulas are available to calculate the ideal CFM rating for a blower motor. Additionally, tables are available to make the process easier including information surrounding CFMs and BTUs. For example; a natural draft furnace needs 100 CFM of fan speed per 10k BTUs of input; an 80%-plus draft furnace needs 130 CFM per 10k BTUs and a 90%-plus furnace needs 150 CFM per 10k BTUs.

Mistake #4: Removing the Door To the Furnace Without Observing Fault/Error Codes

The door on a gas furnace features a safety switch that prevents the burner or fan motor from coming on while it’s open. Sometimes, with a newer system, a fault or error code is triggered in the control board and must be checked before removing the door to the system. Removing the door will open the door switch, clearing the codes.

If you can’t get the system to come back on after closing the door:

- Turn off power to the system

- Prep the blower door

- Check the wiring to the safety switch

- Check and test the installation

Mistake #5: Waiting To Check The Thermostat

Checking the thermostat should be one of the first things you do on a job. Beyond changing the batteries, problems with gas furnaces that result from the thermostat itself include:

- Dust or fuzz that may have collected causing it to malfunction

- Poor wiring

- A wrong date or time on a programmable thermostat

- Lack of power if connected to house wiring

- A blown fuse

- Proper thermostat location(inside wall, 5 ft above a finished floor, away from any direct heat source)

If you suspect the thermostat is bad, place a jumper across the Rh and W terminals – if the unit comes on, it’s likely the thermostat itself is faulty. Additionally, it’s important to check the wires from the thermostat to the furnace if the thermostat was replaced and still won’t come on.

Mistake #6: Overlooking the Gas Valve

If the system isn’t getting fueled through the gas valve, you aren’t going to get a flame at the burners. Here are some gas furnace troubleshooting ideas for a problem with the gas valve:

- Turn the thermostat to the heat setting and raise the temperature above ambient temp

- Open the furnace door and inspect the system

- Using your multimeter, check for 24v going to the gas valve

- Check to see if the inducer fan is running

- Reboot the system using the service switch, remembering that after three attempts the IFC will lock the system out, and see if the ignitor glows

- Use your gas manometer to determine if there’s pressure from gas entering and leaving the valve

- Shut off power to the unit and use your multimeter to check resistance across the leads to the gas valve — infinite resistance would indicate a faulty coil in the gas valve

TIP: To avoid interrupting power to the unit when you remove the access door, put a piece of tape over the contact switch for the door to fool the system into thinking the door is still closed.

Mistake #7: Overlooking or Misdiagnosing Problems at the IFC

Diagnosing issues related to the integrated furnace control (IFC) is especially important because it is essentially the brain of a furnace and controls multiple functions within the system. If an issue is detected, replacing the entire IFC may be the best option. Here are ways to troubleshoot an IFC:

- Turn the thermostat to Heat, raise the temperature setting, open the door and tape over the contact switch (as mentioned above)

- Try rebooting the system using the service switch (as mentioned above, three attempts will cause the system to be locked out)

- With the inducer running, measure voltage across the pressure switch — 24V would indicate a problem

- If the pressure switch tests OK, check for 120V at the hot surface ignitor

Mistake #8: Ignoring Problems With Transformer

A transformer in a gas furnace is essential as it raises or lowers the electricity voltage when traveling from the circuit board to the HVAC unit. Ignoring problems with the transformer could trip the circuit breaker, cause intense humming, or result in the HVAC unit to stop working altogether. Easy ways to troubleshoot a transformer include:

- Turn the thermostat to heat, remove the door, tape the door switch, and check to see if the inducer fan is running.

- If the inducer fan isn’t running, it could be the contact switch for the door or could be the transformer.

- Is the IFC getting 120V of line voltage? Check terminals R and C — do you get a 24V reading?

- Check for any loose connections at the IFC and loose connections on the leads from the transformer to the IFC.

- Check for 24V at the terminals on the secondary side of the transformer — a 0V reading would point to a problem.

- Check its primary side and ensure that 120V is going into the component.

As with all troubleshooting scenarios, your final step should be to turn on the unit at the thermostat, go to a heat register in the residence or building and ensure that heat is moving through the system and the ducts.

Mistake #9: Fail to Notice Problems With Flame Sensor

The flame sensor is a thin metallic rod that receives a small current of electricity from the IFC to confirm that a flame is burning. Though small, a malfunctioning flame sensor can cause issues with the overall system or indicate other problem areas. Simple ways to troubleshoot a flame sensor include:

- Turn the thermostat to Heat, turn the temperature up, remove the door and tape the door switch.

- Reboot the system and check the burners. Do the burners light and stay lit?

- If the burners only stay lit for a few seconds and then kick off, it could indicate a problem with the flame sensor.

- Using your multimeter, measure the dc microamp signal in series to the flame sensor.

If you can detect a measured signal between 1 -8 microamps dc, only for the few seconds that the burners stay on, that indicates a problem with the IFC. If you detect no microamp signal,the flame sensor or the burner ground wire may be fractured. Measure resistance across both the sensor wire and ground wire to determine the which is at fault.

TIP: When running through these diagnostics, don’t forget to look for damaged, corroded or loose wires, as well as a disconnected or improperly connected ground wire.

Mistake #10: Ignoring an Open Pressure Switch

The pressure switch is a safety device that shuts the system down if it detects negative pressure from the draft inducer motor, which would introduce exhaust fumes back into the home. It also is responsible for shutting the system down in the event of a gas leak or a mechanical failure. Troubleshoot the pressure switch by doing the following:

- Raise the thermostat, open the door, tape over the contact switch, look to see if the inducer is running and reboot the system.

- Is the ignitor glowing? The ignitor should glow brightly for several seconds. What’s the voltage across the pressure switch? A 24V reading would indicate an open pressure switch.

- Don’t assume that the pressure switch is bad at this point — instead, check the venting and combustion air intake pipe for obstructions. Often leaves or a bird’s nest can block the system’s outdoor vent in the off season, forcing the pressure switch to shut everything down.

- Inspect the vent for proper design. Proper pitch, length, and termination location are all required to keep the pressure switch from turning the unit off.

Just like in any troubleshooting, diagnosing HVAC problems should be a process of elimination. Think of it as a funnel where you’re starting with the most obvious things first and then work from there.

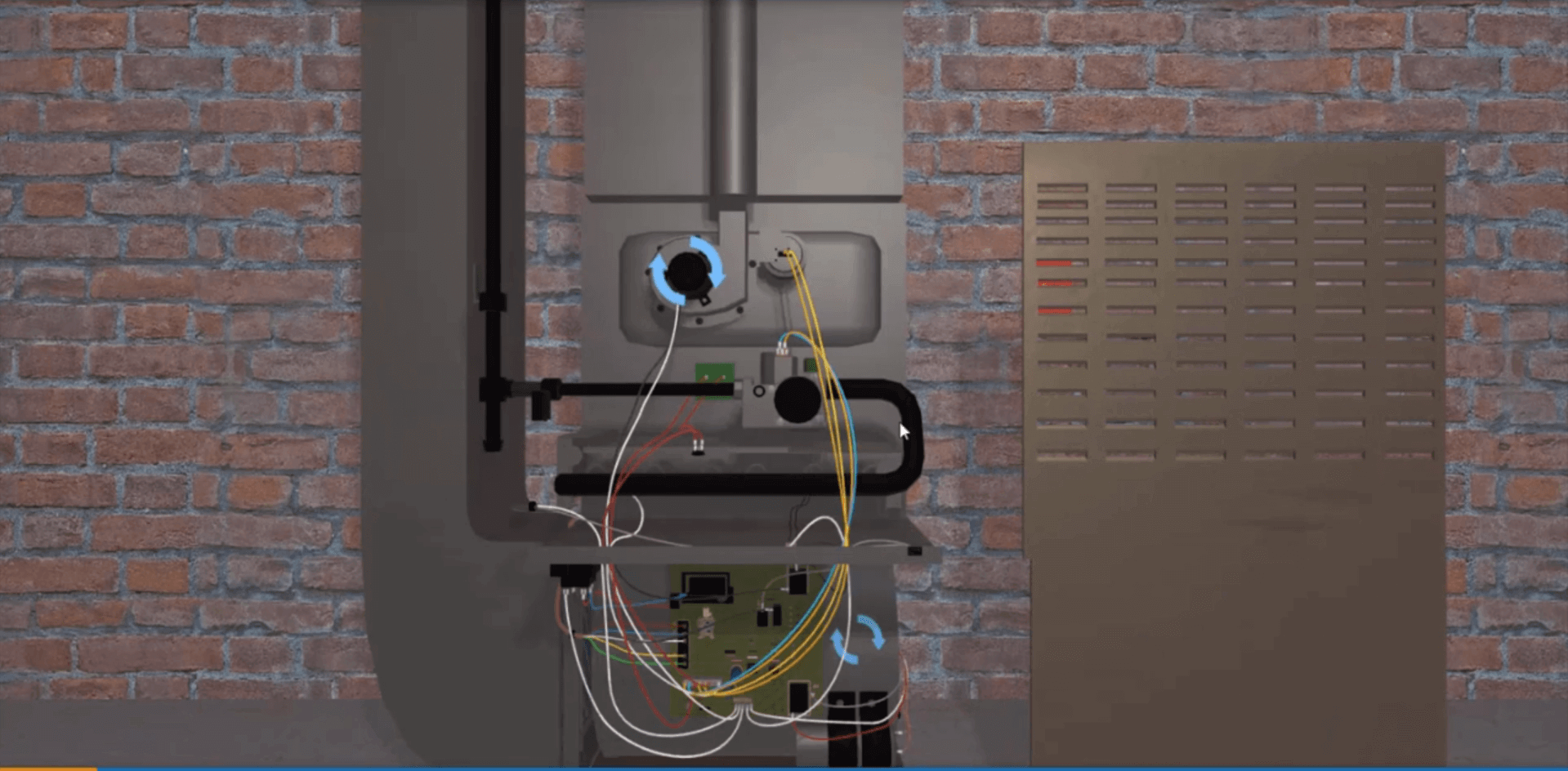

If you’re looking for more at-home opportunities to troubleshoot common faults on a gas furnace, or any other HVAC equipment, online simulations are quickly becoming the go-to method. They guide your learning in a safe, no-fail environment and you can practice as much as you need to feel confident with the real thing in the field.